Hydrogen Applications: PEM Electrolyzers & Fuel Cells

Hydrogen Business Segment —

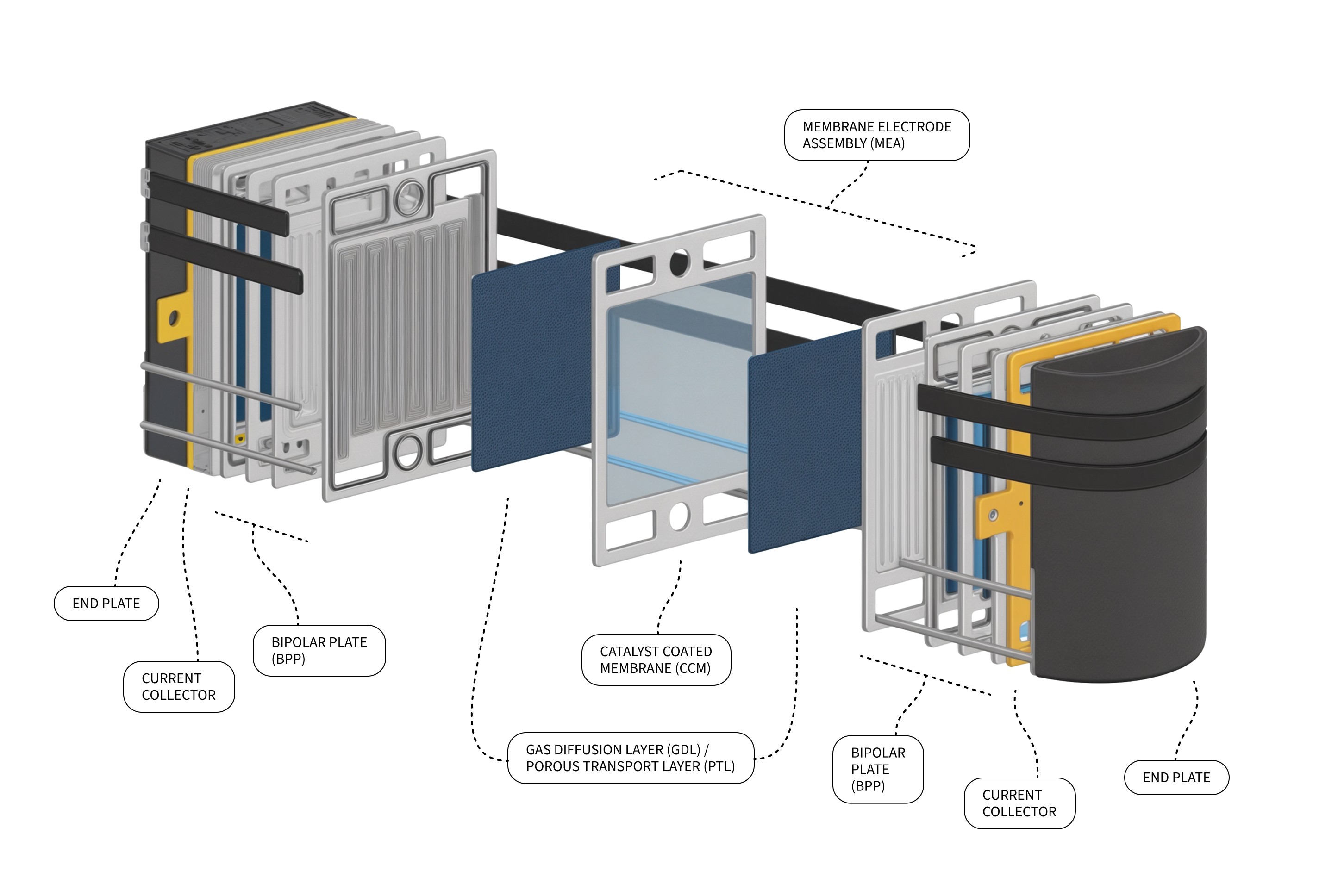

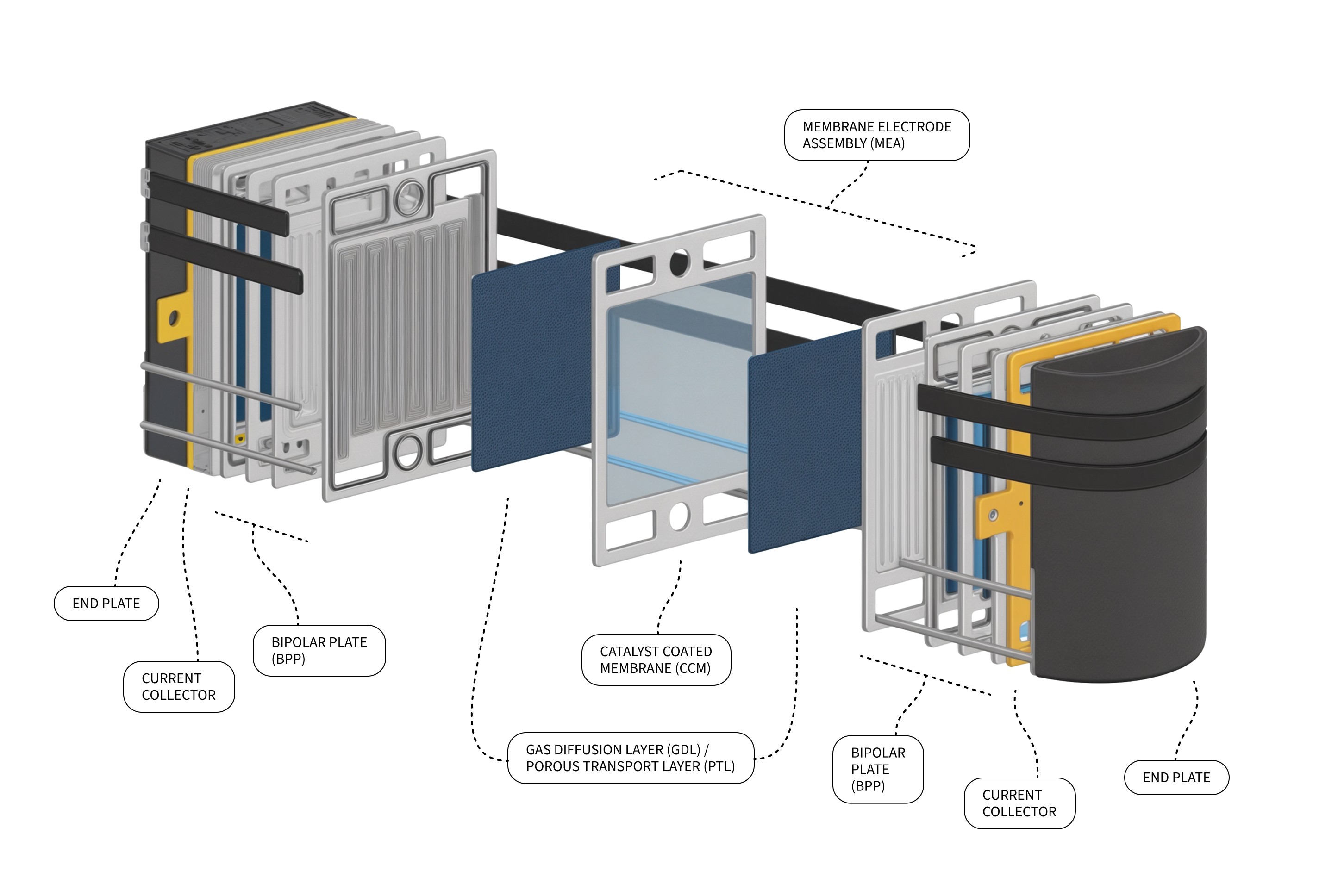

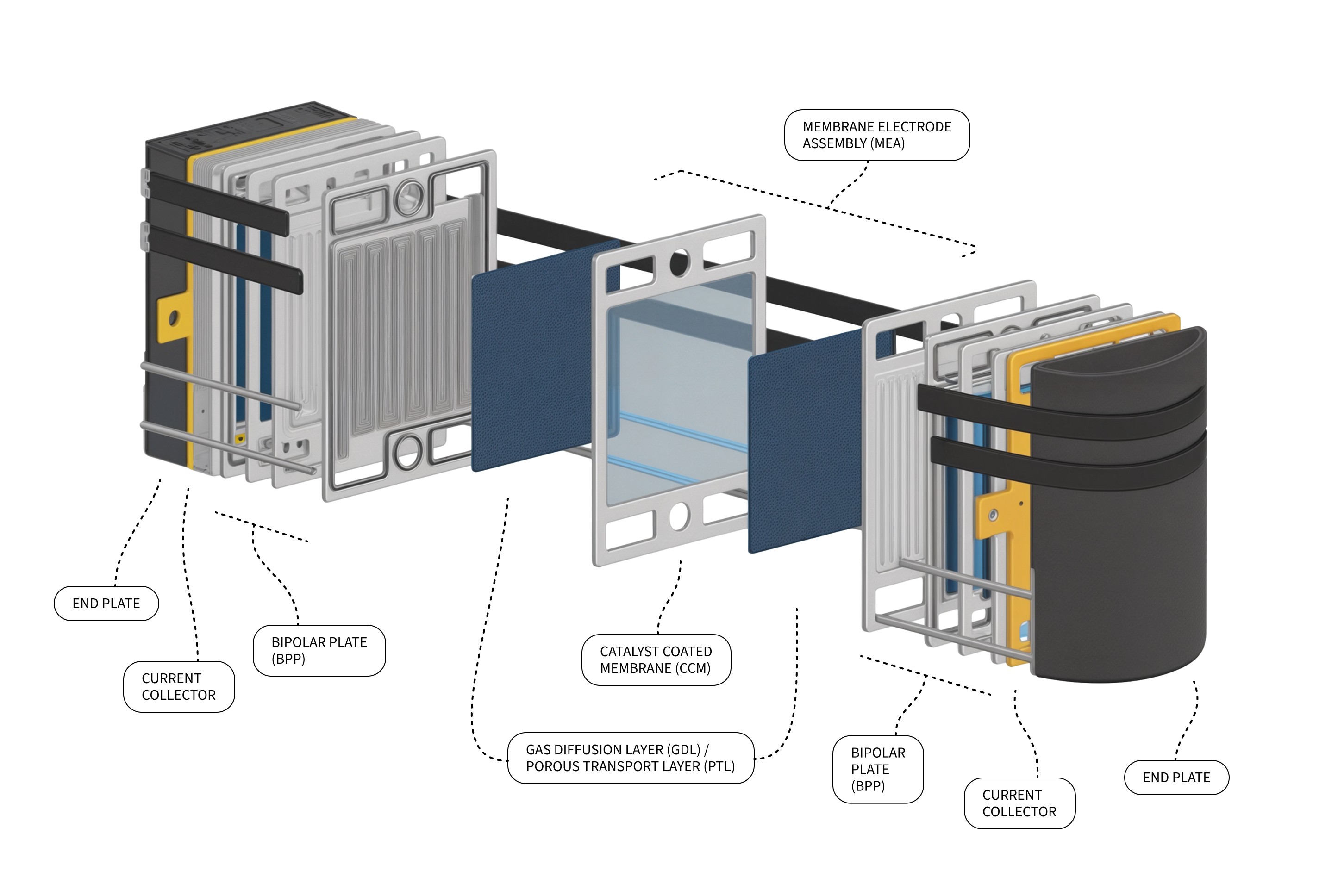

PEM-Electrolyser

Conductivity, Corrosion, and Hydrogen Barrier

PEM-Electrolyzer

Production Sequence

PEM-Electrolyzer

Production Sequence

We develop innovative solutions that enhance production efficiency while reducing resource consumption. Our technologies help minimize waste and optimize manufacturing processes for a more sustainable future.

We develop innovative solutions that enhance production efficiency while reducing resource consumption. Our technologies help minimize waste and optimize manufacturing processes for a more sustainable future.

Current

Collector

Cathode

Anode

Wet-chemical cleaning

PVD coating

Current

Collector

Cathode

Anode

Wet-chemical cleaning

PVD coating

Current

Collector

Cathode

Anode

Wet-chemical cleaning

PVD coating

Bi-

Polar-

Plates

BPP

Wet-chemical cleaning

PVD coating

Bi-

Polar-

Plates

BPP

Wet-chemical cleaning

PVD coating

Bi-

Polar-

Plates

BPP

Wet-chemical cleaning

PVD coating

Gas

Diffusion

Layer

GDL

Wet-chemical cleaning

PVD coating

Gas

Diffusion

Layer

GDL

Wet-chemical cleaning

PVD coating

Gas

Diffusion

Layer

GDL

Wet-chemical cleaning

PVD coating

Catalyst

Coated

Membrane

CCM

PVD

Catalyst

Coated

Membrane

CCM

PVD

Catalyst

Coated

Membrane

CCM

PVD

Porous

Transport

Layer

PTL

Wet-chemical cleaning

PVD coating

Porous

Transport

Layer

PTL

Wet-chemical cleaning

PVD coating

Porous

Transport

Layer

PTL

Wet-chemical cleaning

PVD coating

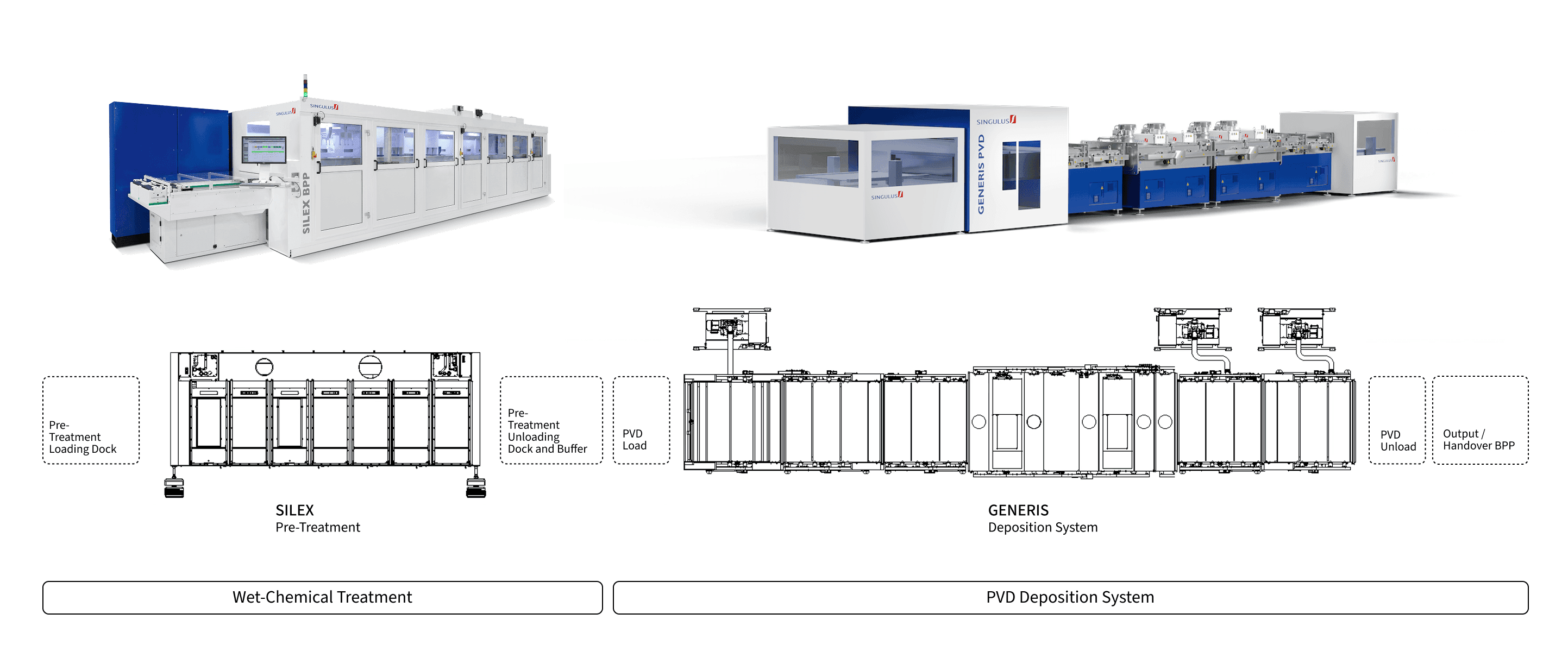

SINGULUS TECHNOLOGIES Equipment at Production Sequence of Hydrogen applications

SINGULUS TECHNOLOGIES Equipment at Production Sequence of Hydrogen applications

SINGULUS TECHNOLOGIES AG provides Single Production Equipement

for vacuum- and wet processing applications

SINGULUS TECHNOLOGIES AG provides Single Production Equipement for vacuum- and wet processing applications

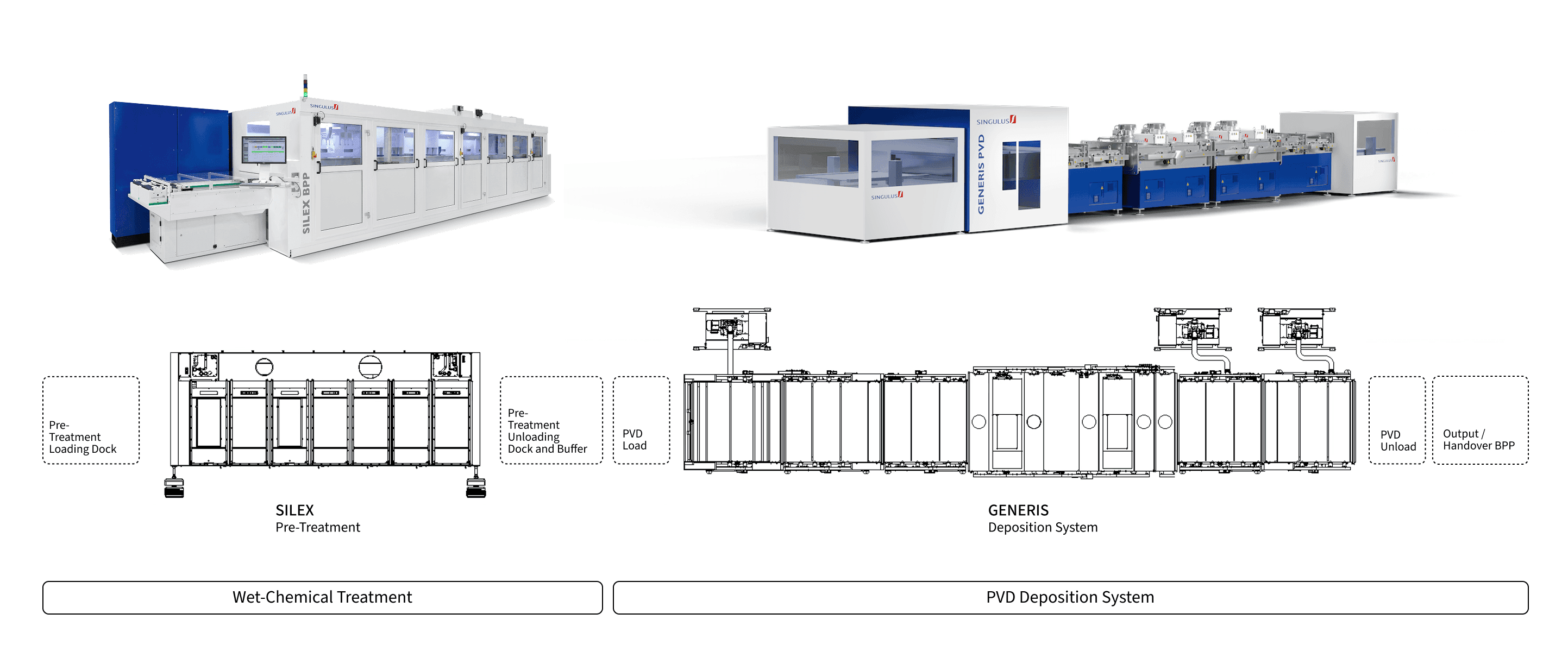

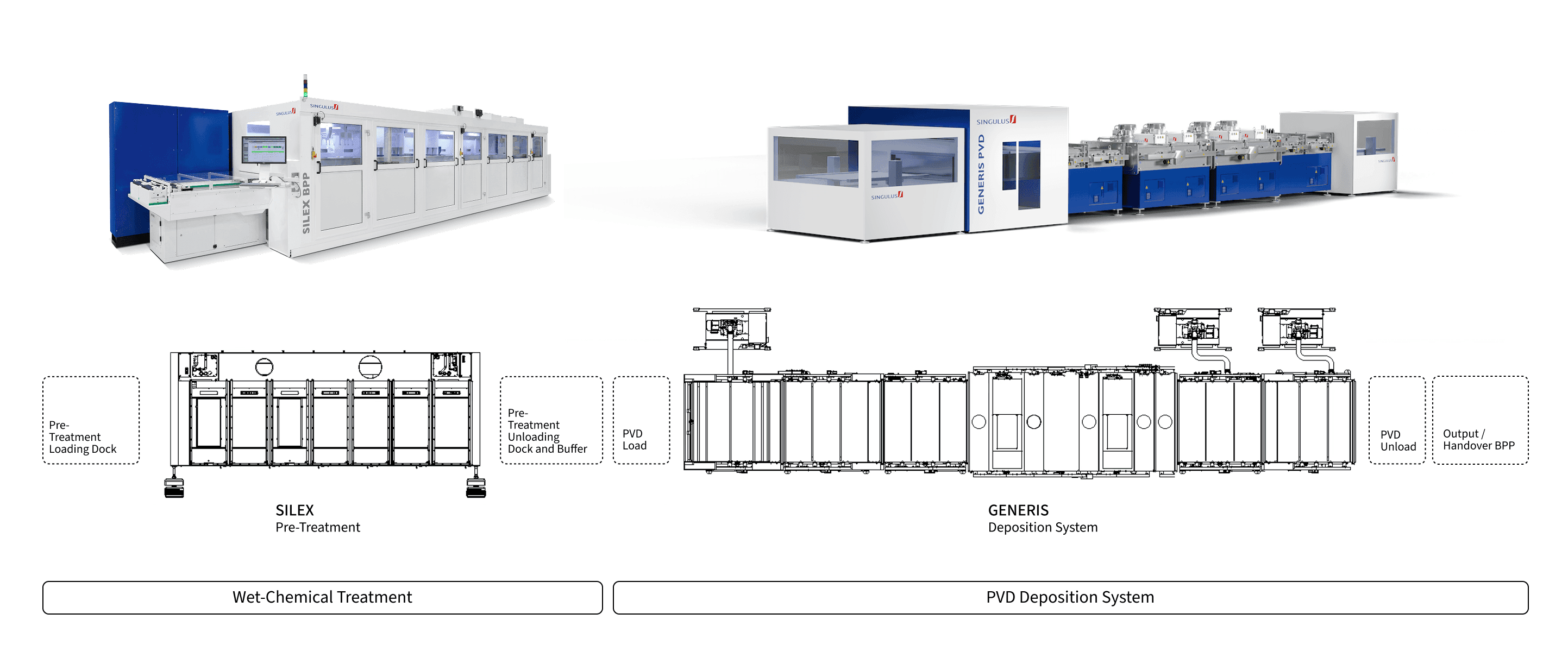

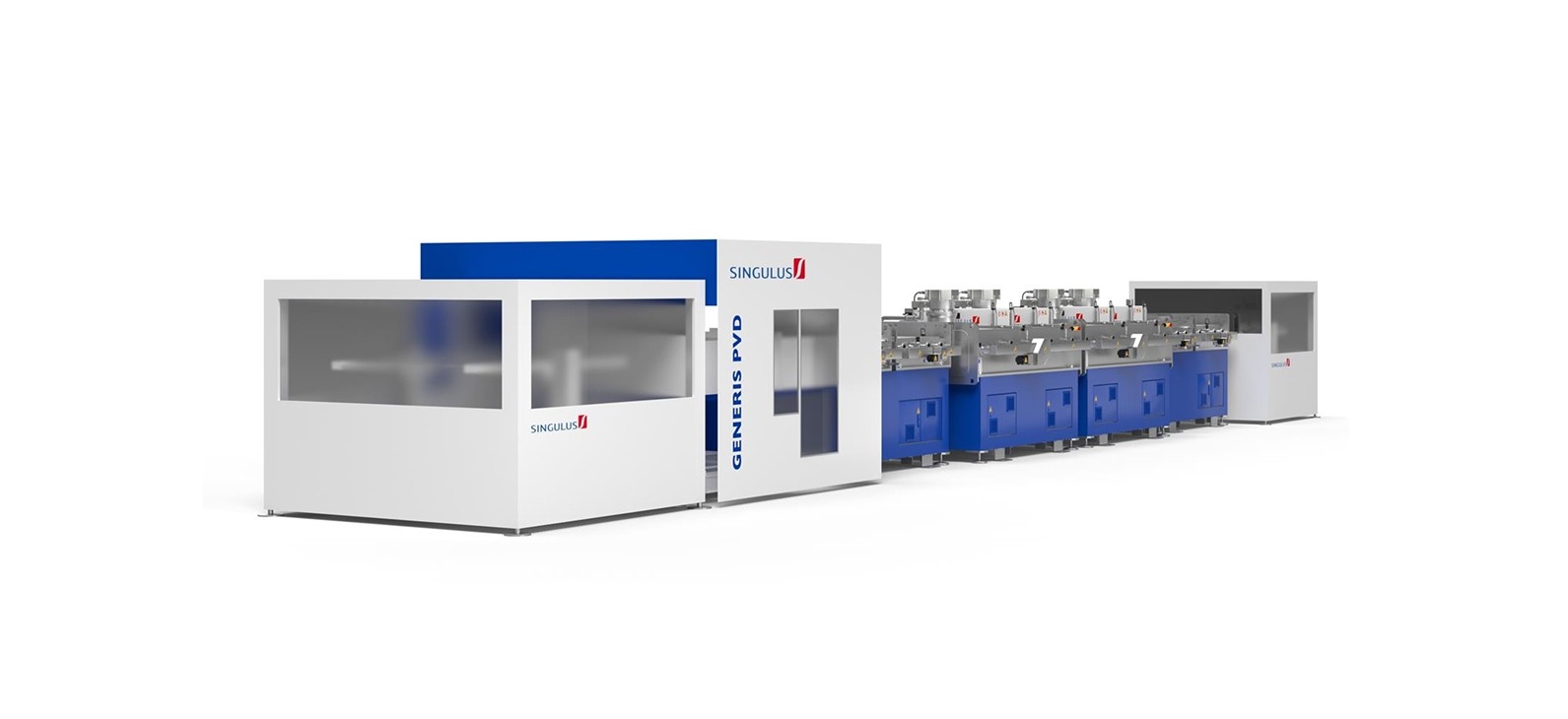

Combined Production Flow for PEM electrolyzer and fuel cells components

Integrating SILEX (WET) and GENERIS (PVD)

By integrating SILEX (WET) and GENERIS (PVD) into a combined product flow, we offer a unified solution that simplifies your experience. This integration ensures seamless communication between systems, a single point of contact, and a consistent operating interface, all of which enhance operational efficiency and customer convenience.

By integrating SILEX (WET) and GENERIS (PVD) into a combined product flow, we offer a unified solution that simplifies your experience. This integration ensures seamless communication between systems, a single point of contact, and a consistent operating interface, all of which enhance operational efficiency and customer convenience.

By integrating SILEX (WET) and GENERIS (PVD) into a combined product flow, we offer a unified solution that simplifies your experience. This integration ensures seamless communication between systems, a single point of contact, and a consistent operating interface, all of which enhance operational efficiency and customer convenience.

One Contact

One Contact

System Sync

System Sync

Unified Interface

Unified Interface

From Lab to Fab

Cleaning and Etching

Suitable for Hydrofluoric acid (HF), Aqua regia (HCl), Potassium hydroxide (KOH), and many more

Ozone System for enhanced cleaning & etching (reduction of COO)

Water-cascading for optimal rinsing quality by low water consumption

80°C N2 drying oven

Advanced process control by onboard data tracking

Suitable for Hydrofluoric acid (HF), Aqua regia (HCl), Potassium hydroxide (KOH), and many more

Ozone System for enhanced cleaning & etching (reduction of COO)

Water-cascading for optimal rinsing quality by low water consumption

80°C N2 drying oven

Advanced process control by onboard data tracking

Wet Chemical Benches for Lab R&D

SILEX for Production

Wet Chemical Treatment

SILEX system for efficient cleaning, residue removal and enhanced deposition pretreatment

SILEX for cleaning and etching of e.g. BPPs, effective removal of manufacturing grease and surface oxides

SILEX for cleaning and etching of e.g. BPPs, effective removal of manufacturing grease and surface oxides

example image

example image

example image

example image

example image

example image

Features

Wet Chemical System for the cleaning and pretreatment of BPP and components of electrolyzer or fuel cells

Wet Chemical System for the cleaning and pretreatment of BPP and components of electrolyzer or fuel cells

High throughput performance

High throughput performance

Compatible for various geometries and components

Compatible for various geometries and components

Optimized Cost of Ownership for efficient cleaning & etching

Optimized Cost of Ownership for efficient cleaning & etching

Advanced process control by onboard data-log and event tracking and individual process sequencing

Advanced process control by onboard data-log and event tracking and individual process sequencing

Compact footprint with integrated switch boxes

Compact footprint with integrated switch boxes

Fast Installation and start-up by modular design

Fast Installation and start-up by modular design

Inhouse Process Carrier design

Inhouse Process Carrier design

Dedicated Facility-/Utility package available (e.g. chemical supply system)

Dedicated Facility-/Utility package available (e.g. chemical supply system)

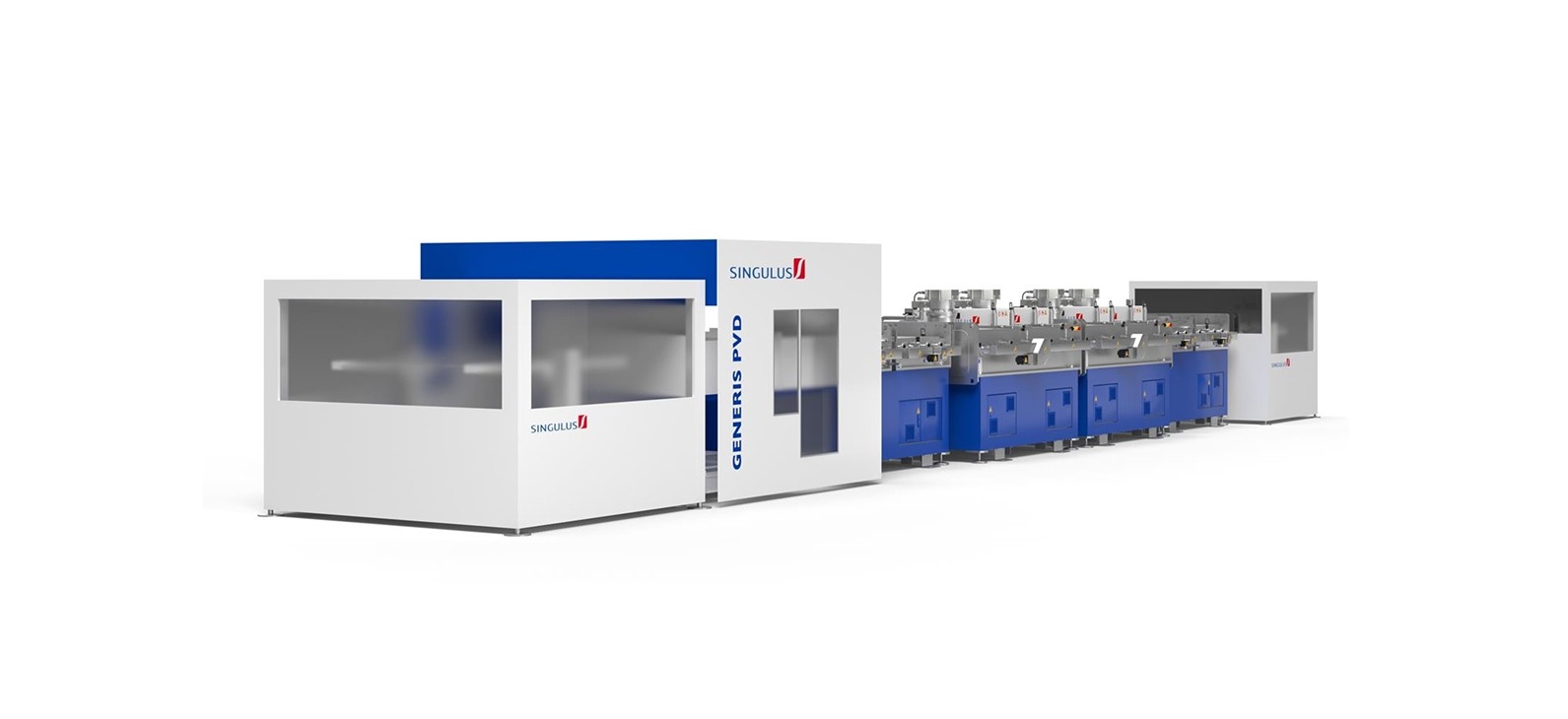

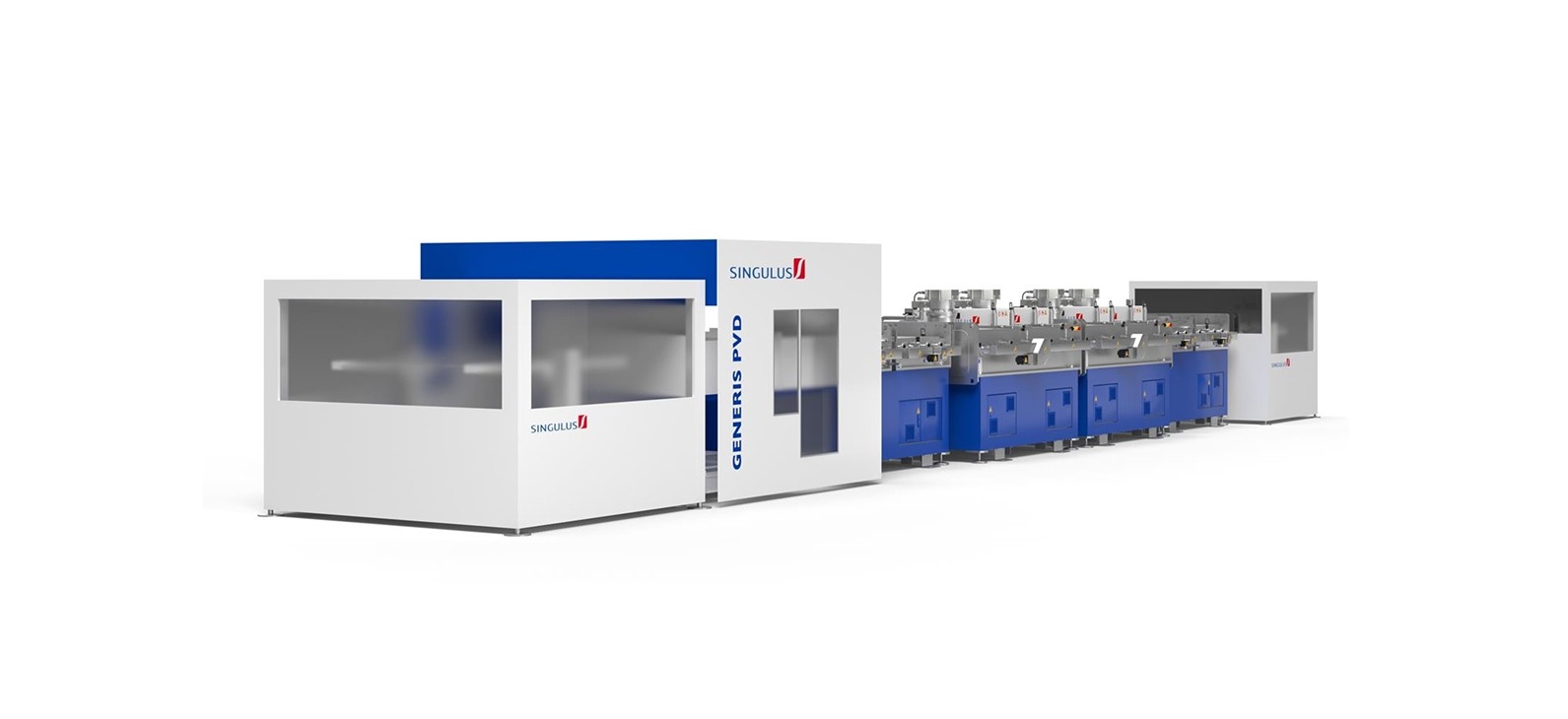

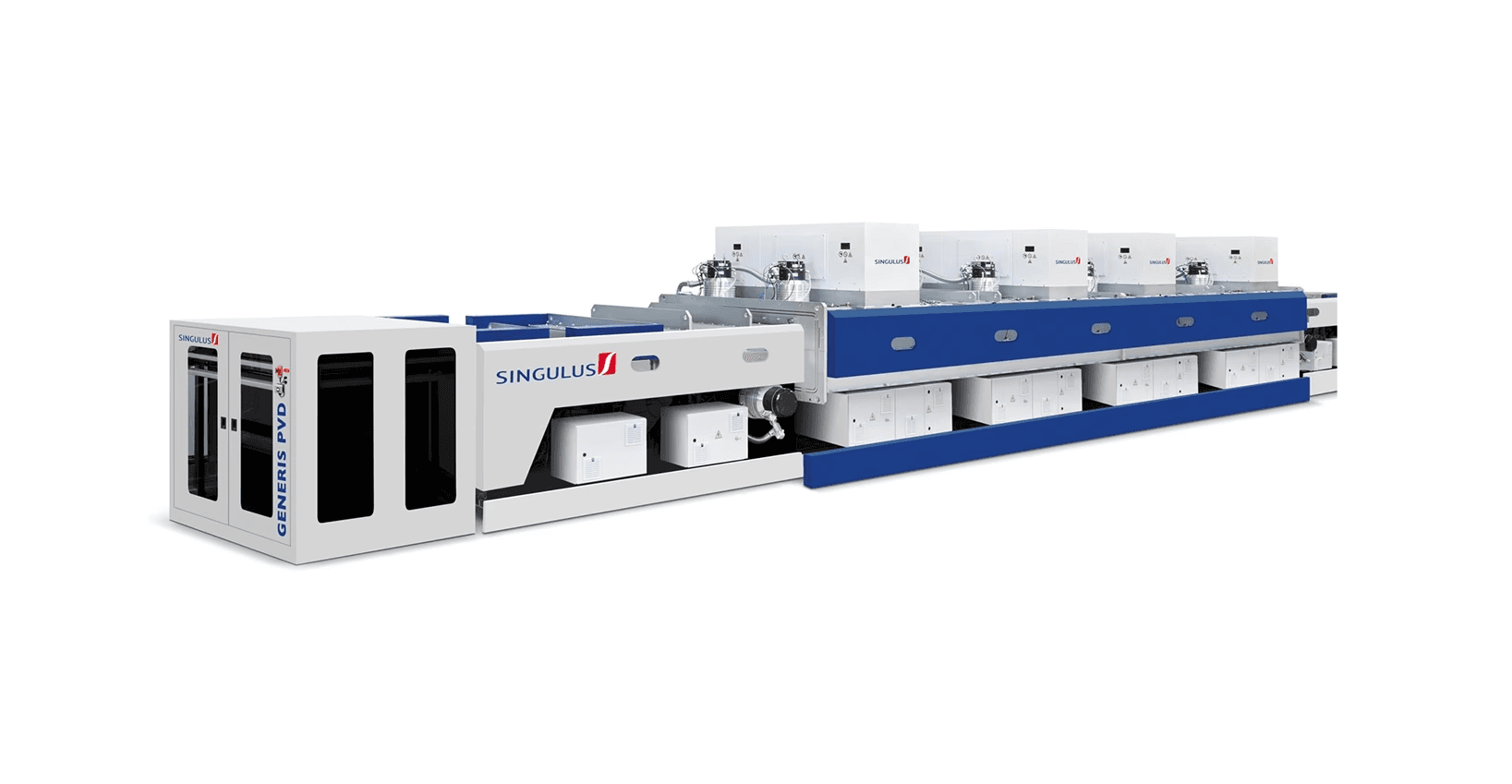

From Lab to Fab - PVD deposition system

PVD deposition system

Scale up

Scale up

Smooth transition from Lab (0.3m x 0.7m) to Fab (2.5m x 3m) equipment with high uniformity ±3 %

Smooth transition from Lab (0.3m x 0.7m) to Fab (2.5m x 3m) equipment with high uniformity ±3 %

GENERIS 900 for Lab R&D

GENERIS 1800 for high-throughput production

VISTARIS 600 for Lab R&D

VISTARIS 1800 for high-throughput production

PVD Sputter Portfolio

For Highly Controlled Thin-Film Coating of BPPs and other components

Application

Application

Metallization, Barrier Coating, Bipolar Plates for Electrolyzer and Fuel cells

Metallization, Barrier Coating, Bipolar Plates for Electrolyzer and Fuel cells

Technologies

Technologies

Substate pretreatment, PVD magnetron sputtering, Heating

Substate pretreatment, PVD magnetron sputtering, Heating

Coatings

Coatings

Au, Pt, Ir, C, Cr, CrN and other Metal Nitrides, single and double sided

Au, Pt, Ir, C, Cr, CrN and other Metal Nitrides, single and double sided

GENERIS 700 S

Multipass

GENERIS 1250 M

Inline

GENERIS 1800 L

Inline

Annual Output*

Annual Output*

200k

200k

GENERIS 700 S

Multipass

GENERIS 700 S

Multipass

Coating Area:

450 x 1000 mm

Coating Area:

450 x 1000 mm

up to

3Mio

up to

3Mio

GENERIS 700

Inline

GENERIS 700

Inline

Coating Area:

450 x 1000 mm

Coating Area:

450 x 1000 mm

up to

5Mio

up to

5Mio

GENERIS 1250 M

Inline

GENERIS 1250 M

Inline

Coating Area:

850 x 1600 mm

Coating Area:

850 x 1600 mm

up to

10,5Mio

up to

10,5Mio

GENERIS 1800 L

Inline

GENERIS 1800 L

Inline

Coating Area:

1400 x 1600 mm

Coating Area:

1400 x 1600 mm

*substrate size: 15 x 40 cm, 8400h production hours

*substrate size: 15 x 40 cm, 8400h production hours

Contact Us

Contact Us

Discover how our customized PVD and wet-chemical process solutions can enhance your production efficiency and conserve resources.

Contact SINGULUS TECHNOLOGIES today and let’s develop sustainable innovations together.

Discover how our customized PVD and wet-chemical process solutions can enhance your production efficiency and conserve resources.

Contact SINGULUS TECHNOLOGIES today and let’s develop sustainable innovations together.

Terms of Business

Data Protection

Imprint

© 2025 SINGULUS TECHNOLOGIES AG

Terms of Business

Data Protection

Imprint

© 2025 SINGULUS TECHNOLOGIES AG